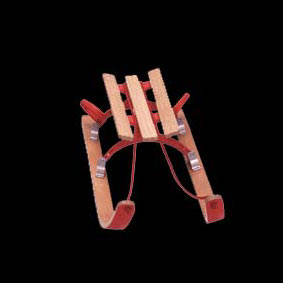

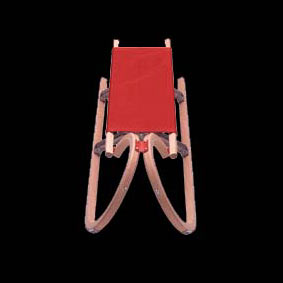

Treatment

from the raw plank up to the final product

Starting from our raw wood stock with attached

drying installation we are able to produce all pre-cut

parts short-term and scaled.

Our programm with its wide variety of larger and smaller

parts allows us an optimum utilisation of the raw wood

and an extensive minimisation of the wood waste.

The processing is carried out according to the requirements

on planing machine, on turning and milling machines

for series productions respectively on turning lathes

and milling machines for single-part production and

small quantities.

Up to a length of 1000 mm we give the lumbers the chamfers,

curves, forms and outlines which you define.

For the fitting of drillings, slots, cutouts and millings

we use CNC-milling machines and diverse drilling machines.

At the end the lumbers can be varnished by us or treated

with ecological waxes and oils. As technology we have

available an automatic cycle spray plant, diverse submerge

basins and several varnishing barrels.

.If requested we are imprinting your wood parts with

logos, characters, etc. in branding iron respectively

screen printing technique |